Concept

Dial was the end result of my first long-term, comprehensive university product design project. The brief for the project invited us to develop a “personal marking device”, typically in the form of a pen, that represented our individual identities as budding designers. We were also required to leverage the university’s Stratasys J-850 multi-material 3d printer in the development of our assignment. With the support of my lecturer, I decided against developing a pen, and instead resolved to develop a practical workshop tool instead. Although I liked the idea of developing a pen, it did not align with my personal identity as a designer, as I have Dysgraphia, a learning disability that slightly impacts my communication through hand-written language.

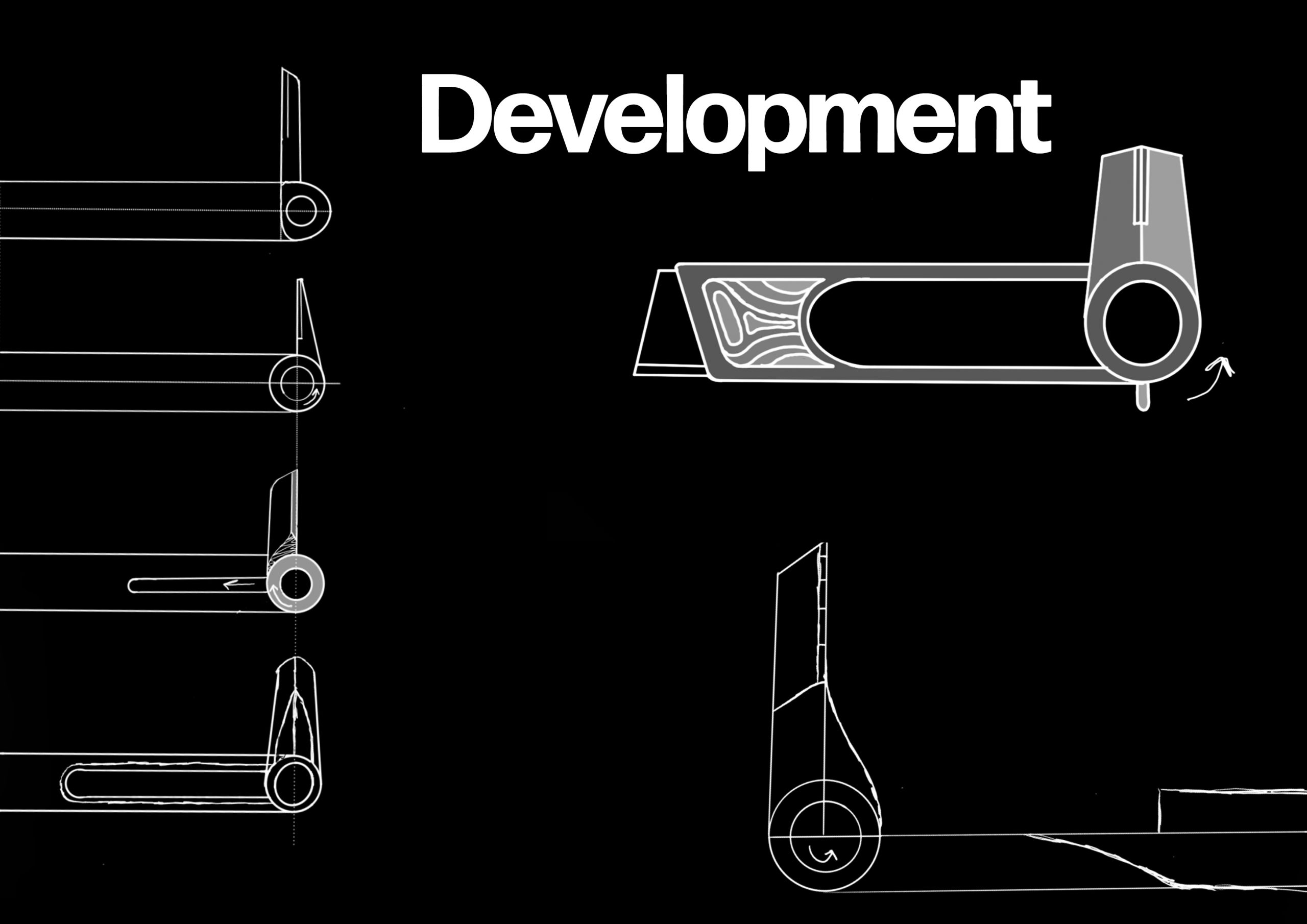

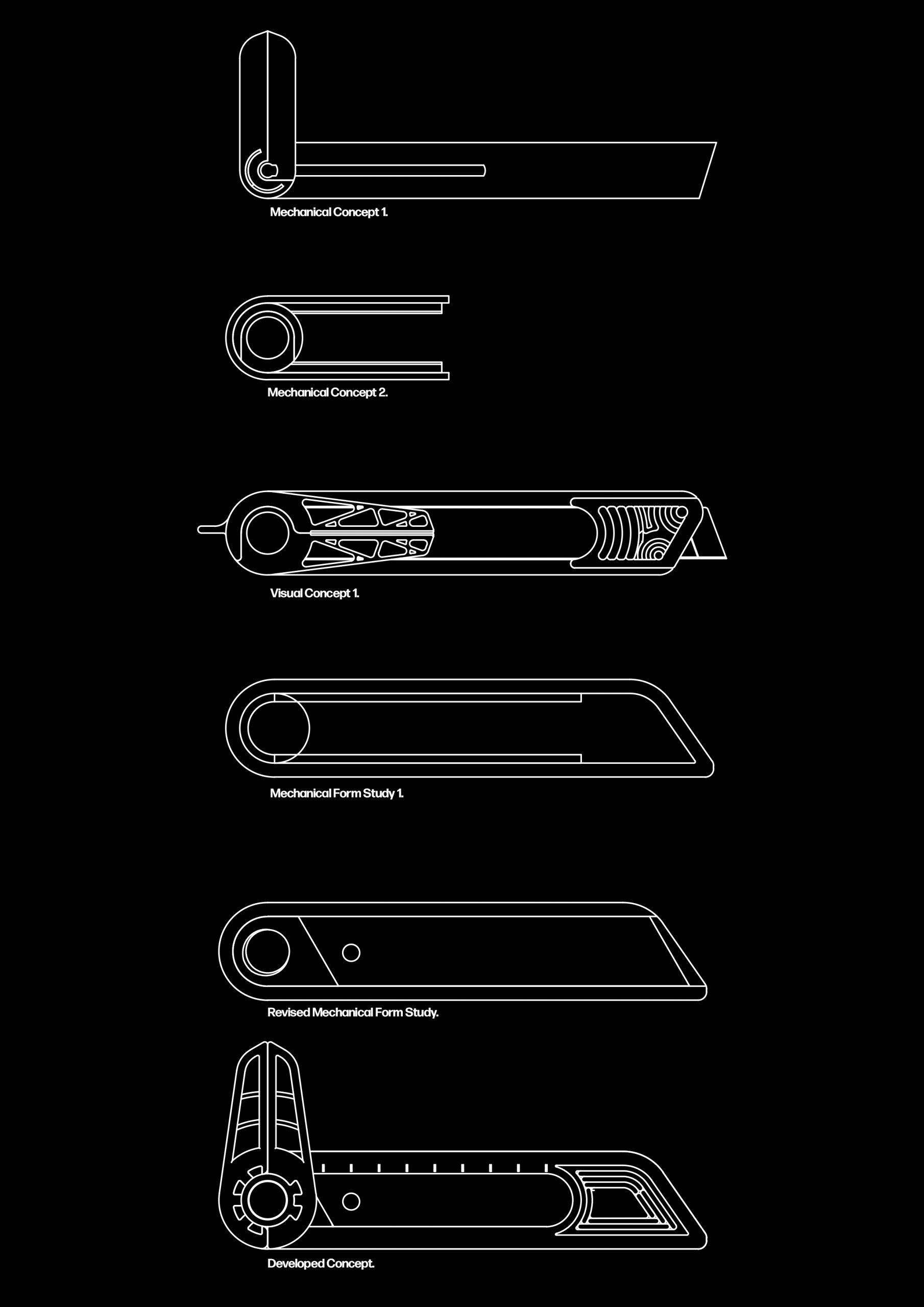

Development

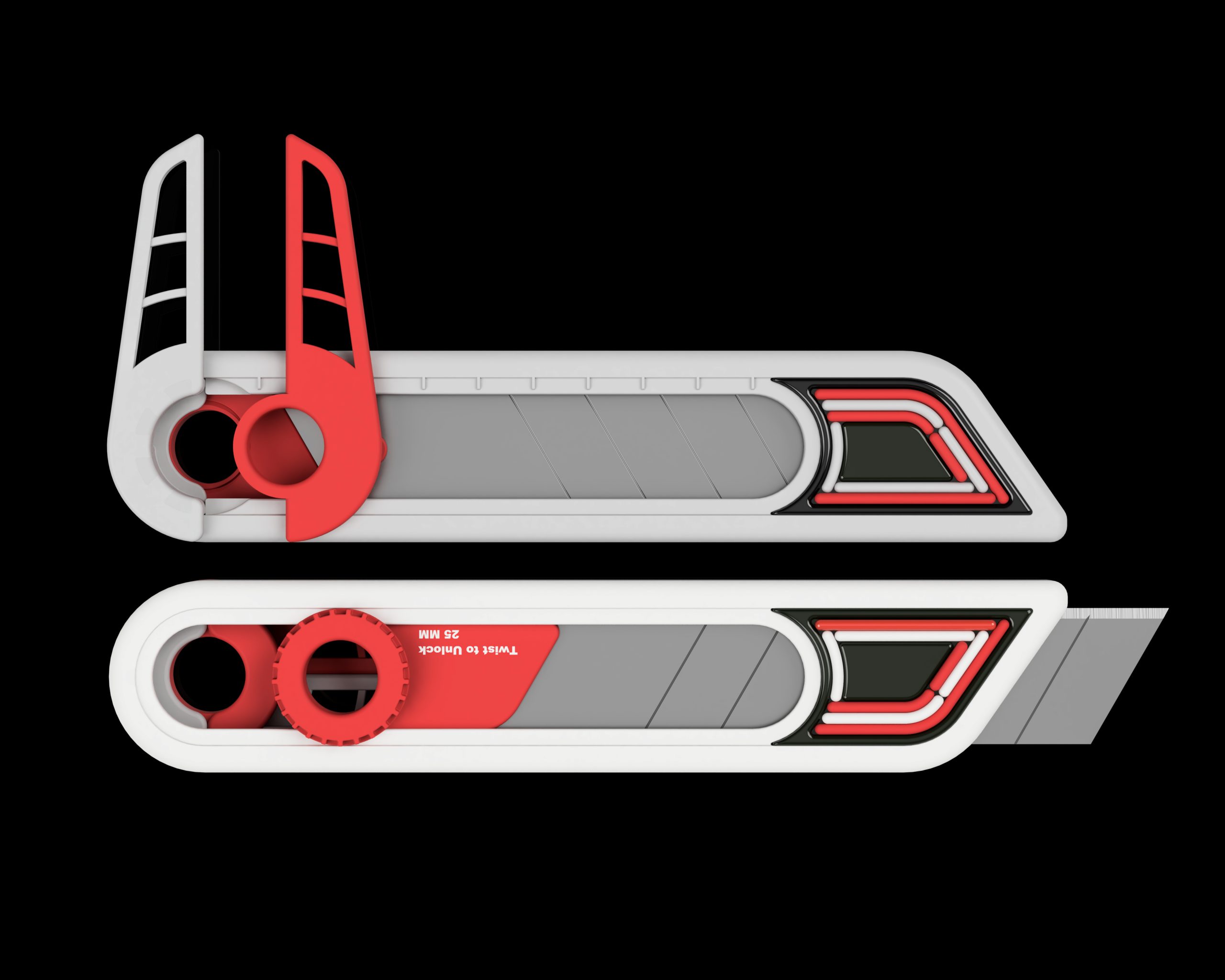

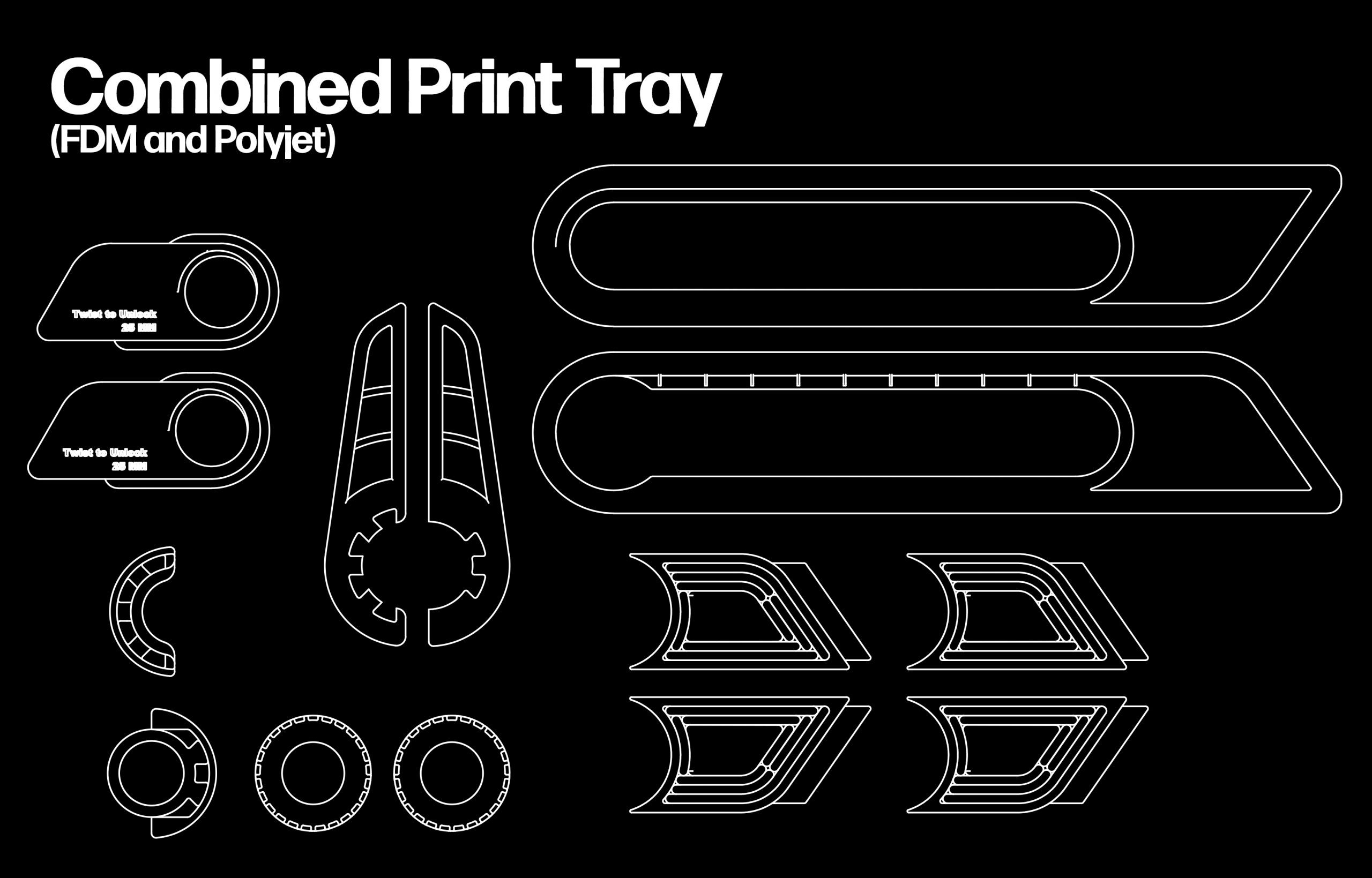

After exploring a range of workshop tools, I eventually landed upon the concept of fusing two tools that I found I needed the most while working in a shop (Callipers and a snap-blade knife), into a single, convenient assembly that would take up less space in my pockets. I felt that this particular concept better reflected my identity as a designer through its use case and conceptual background, while also lending me more experience with complex multi-part assemblies.

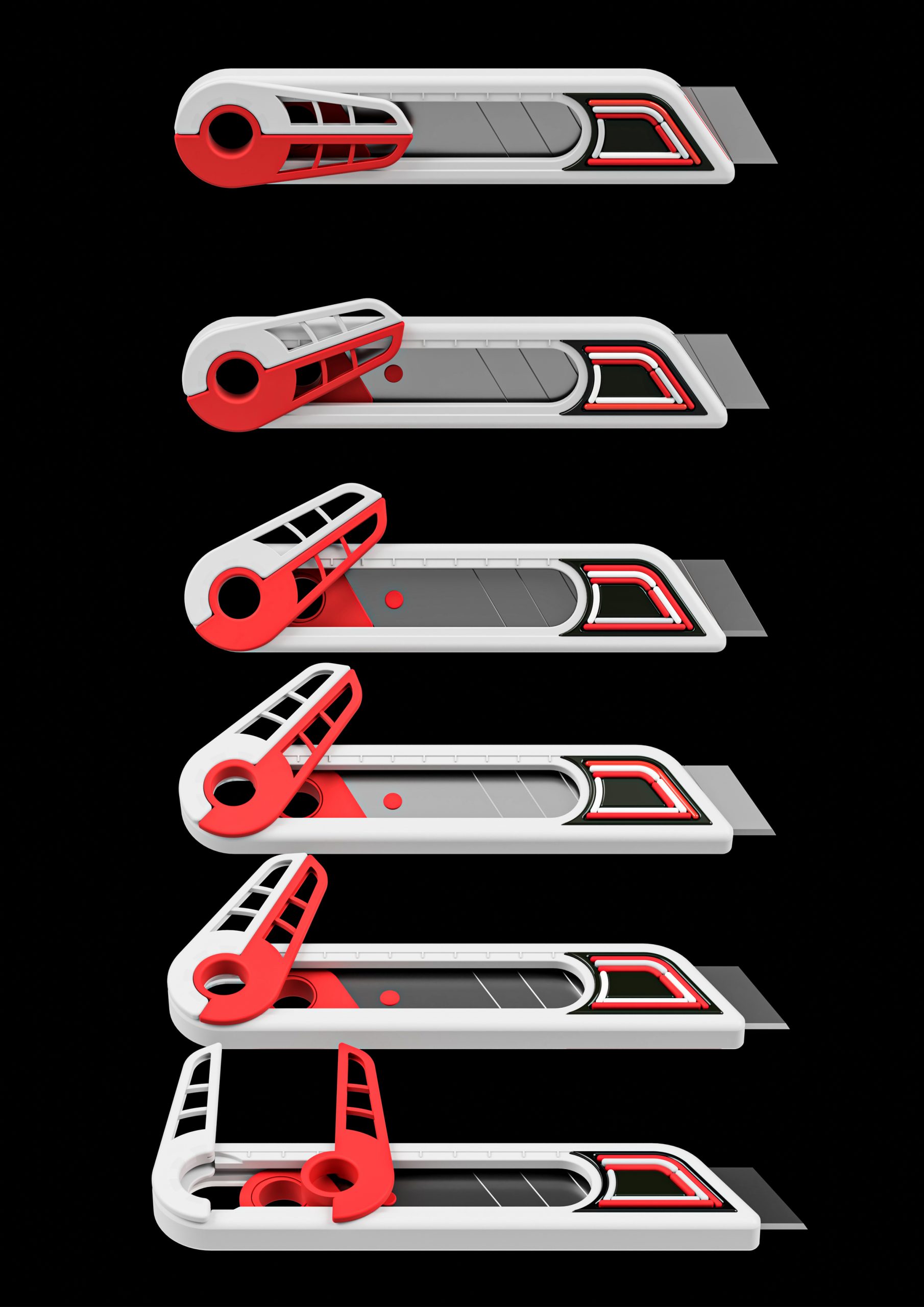

Stratasys’s J-850 is an immensely capable voxel printer, that can create components with variable levels of density while allowing for colour input at every level. My eventual product took advantage of these particular talents, as well as the J-850’s exceptional dimensional accuracy by modulating the density of the retaining mechanism for the blade and grip for increased comfort, while also designing each interfacing component to be readily replaced or customized. The J-850’s excellent tolerances also aided my development of the rotating calliper assembly, which was particularly difficult, as the calliper blades needed to ‘lock’ when closed.