Concept

E2 represents the interfacing of cutting-edge digital development and timeless physical craft. Procedural modelling is an increasingly important tool in the digital design process, but must be grounded in a thorough understanding of the demands of physical production to be useful. In an effort to develop these skills further, I took part in a course in my second year of study that explored the interfacing of digital manufacturing and physical making in the context of furniture design. Our project brief called for the development of an object intended for seating, that was comprised of a procedurally designed, SLS printed component, and a traditionally designed and hand-made component.

Development

Procedural modelling has a plethora of distinct advantages for the design process. For this assignment, I focused on the rapid iterative capabilities of the technology, as well as the high level of sensitivity and control that can be achieved.

This project was undertaken in two stages. The first stage of the project saw extremely rapid conceptual ideation and visual iteration, as we aimed to undertake a minimum of 100 distinct iterative steps. This part of the project gave me the space to rapidly learn multiple procedural techniques in Blender, while gaining a level of sensitivity and control with each successive iteration. I completed the first stage of the project with a core concept for my chair, and the confidence to develop the idea for the real world.

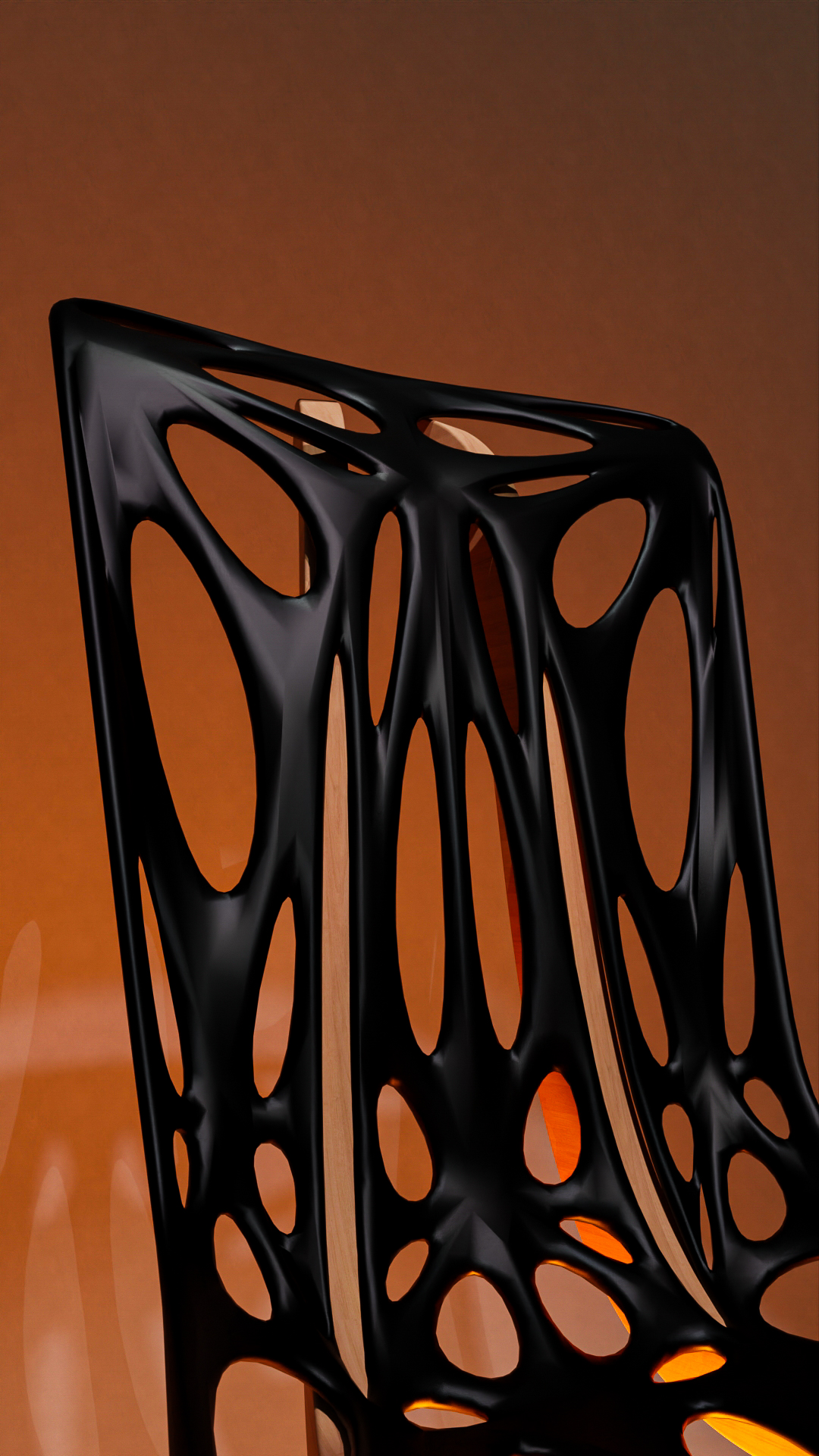

The second stage of the project saw the development of our end concept into a realistic product. My chair concept was largely focused on the selective distribution of material in the form of the chair to the regions that were most necessary for structural support and comfort. I’ve been fascinated for a while with the work of Charles and Ray Eames and took inspiration in their “low shell chair” from the 60s. I saw their leveraging of emerging technology (composite manufacturing), for a clean, nearly weightless form as a distillation of what I hoped to learn. I brought that philosophy into this project and leveraged emerging procedural techniques to realize my chair’s eventual form. I designed the base of my chair to contrast its digital counterpart in its assembly and planar nature. The base was constructed of thin ply, with the intent that the full-size version would be made of sections of cedar. The digital component of my chair was SLS printed, with the full-size version being either large format FDM printed, or constructed of chop strand fibreglass.